After attending this year’s virtual Supply Chain Summit, we had the opportunity to bring back our Supply Chain – Ask an Expert series. I am delighted to have global supply chain leader, Farzana Shubarna, as my first interview partner.

Farzana is an industry agnostic global supply chain leader who has worked across the Americas, APAC, and Europe for the FMCG, Specialty Chemical and Nutrition industries. Farzana’s supply chain leadership journey over past two decades includes key industry leaders like AB-InBev, L’Oréal, DSM, and Unilever. Most recently, Farzana joined the Unilever Supply Chain team, to lead the creation of the Centre of Excellence for the USD 10 Billion Unilever 3rd party manufacturing organization.

Farzana is an industry agnostic global supply chain leader who has worked across the Americas, APAC, and Europe for the FMCG, Specialty Chemical and Nutrition industries. Farzana’s supply chain leadership journey over past two decades includes key industry leaders like AB-InBev, L’Oréal, DSM, and Unilever. Most recently, Farzana joined the Unilever Supply Chain team, to lead the creation of the Centre of Excellence for the USD 10 Billion Unilever 3rd party manufacturing organization.

She specializes in new generation “GLOCAL” strategy to deliver desired growth in all business cycles and economic climate. Previously, Farzana headed the end-to-end operation for DSM APAC, Animal Nutrition Division. Her scope involved leading APAC Strategic Procurement, Supply Chain, Manufacturing and Capital Investment teams to deliver a seamless service experience for customers across 23 countries in Asia and Australia.

Emilia Ashton (EA): You’ve worked in both North America and more recently in Asia. Do you find the way in which supply chains operate differs across continents and if so how? What tips would you give for anyone wanting to run successful supply chains across continents?

Farzana Shubarna (FS) : Absolutely. The organizational design, the operating models and cultural uniqueness is very different in the Americas vs. in the Asia Pacific. In my previous roles I was managing supply chain operation for the North and Central America, where most of the trade and logistics networks were designed and operated based on very similar terms and conditions. The sourcing and distribution models were well established allowing focus on productivity gain along with optimization. Also, the markets and governing authorities were mature enough to have sound regulatory and export-import protocol for the industry members.

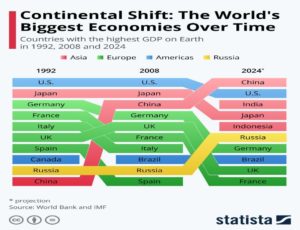

In comparison, Asia and Australian markets are extremely fragmented and fast evolving. In the APAC region, there are multiple unique and independent sub-regional supply chain clusters. We have ASEAN (Singapore, Malaysia, Vietnam, Philippines, Indonesia etc), mainland China, the North Asia ( Japan, Korea, Taiwan, Hong Kong etc), the SEA/SAARC (India, Pakistan, Bangladesh, Sri Lanka etc) and Oceania ( Australia, New Zeeland). There is a very distinctive and unique: supply chain design, organizational model and governing protocol/rules, which exists in each of these sub-regions. Asian GDP growth rate is highest in the world, exceeding Europe, and North America. The key focus for supply chain leaders in APAC is to co-create and shape the next generation supply chain models, support the fast business growth, leverage the complex network of logistics and transport to extract the best practices by virtue of knowledge sharing. Supply Chain leaders have more direct and bigger contribution in APAC when it comes to business success through customer service satisfaction and cost optimization.

I must add that, in Asia Pacific, due to emerging maturity of the industrial economy, supply chain leaders are constantly faced with underdeveloped laws and policies related to safety and sustainability. So apart from just managing supply chain for our organizations, we are also actively involved with the thought leaders and governance authorities to design a framework of sound government policies and laws. This is our duty towards environment and society which must be well addressed.

Not to forget that, in Asia and Oceania, leaders must be very mindful and versed about local cultural norms that flows deeply in the business relations. A non-traditional communication or operating practice may very well cost a long-term business relationship. Hence, just being good at function is not good enough, being adept to culture is equally important. Overall a leadership role in Supply Chain in APAC is more complex and involved beyond function than in the Americas.

EA: What are the three most important attributes of successful supply chain management?

FS: I like to approach this question as the most important attributes of Supply Chain Leadership vs. Supply Chain Management because at the end of the day, to achieve our goals, beyond the knowledge and expertise of SCM tools and processes, we must know how to lead and inspire teams of people.

Let me elaborate on these elements…

First, supply chain leaders must be Active Learners – not only they ought to know the industry standard process and best practices but also take part in the knowledge sharing and learning process of cutting-edge next generation tools and processes. We must adopt technology and innovation (AI, ML, IoT, BC etc) as enablers vs. career deterrent. This mindset of learning also needs to extend beyond the function of supply chain into other core functions including but not limited to product innovation, sales/marketing, and finance. In the ever so integrated landscape of matrix organizations, supply chain leaders cannot just operate in their own bubble; they have to be versed at cross functional processes and interests, to be key contributors in the overall success of the organization.

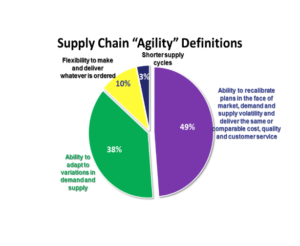

Second key success enabler of supply chain organization/operation is the Agility and Adaptability to change, resulting into resilience and sustainable business continuity. This characteristic must be imbedded in the designed processes and the organizational culture simultaneously. The fastest tool is only as fast as the user and usage.

Digital tools are very supportive to this agility model where validation and frequent re-calibration is crucial to the effectiveness of the designed continuity plan. Also, the importance of “agility mindset” cannot be emphasized enough as I said, the fastest tool is only as fast as the user or usage frequency.

Last but not least, the success of supply chain leadership and organization must be directly aligned and integrated with the success of the overall business and the organizational goal. Why I emphasise this as the third most critical element is because often, I find supply chain professionals get busy with internal KPIs and productivity initiatives that are NOT linked to overall business growth. Those KPIs and investments are non-value added and ultimately create a silo minded SCM culture that is counter-productive for any business. So, supply chain leaders and practitioners must work on customer satisfaction and bottom-line improvement that lead to strategic partnership with other business stakeholders and promote collaboration and credibility.

EA: The pandemic has severely affected supply chains. How do you think leaders and organisations should evolve in a Post-Covid-19 economy?

FS: I think the impact of Covid-19 on supply chain organizations is very timely, effective, and positive. The activation and acceleration that Covid-19 has generated towards digital transformation, organizational agility, effective business continuity plan, legitimate talent management and action-oriented sustainability is revolutionary. Covid-19 fast tracked decades of stagnation in our business actions into months execution.

As I said during the Global Supply Chain Summit 2020 that we should not waste a good crisis, and this is NOT the last crisis we will face in our careers. So, there could not be a better learning opportunity than Covid-19. My advice to my supply chain peers is: let us leverage this momentum to evaluate and invest into the right processes and tools that make us growth friendly and crisis ready. Our teams are our biggest assets and we must not forget to take care of them and “knowledge-nourish” them to lead us beyond the recovery

from Covid-19. I contributed to a whitepaper with Accenture and the infographic summarizes what ought to be our focus now.

I envision the leaders and organizations will evolve to be more collaborative internally (cross functional) and externally (eco-system of customer, supplier, service providers), globally informed-locally equipped (GLOCAL) and digitally fluent. Our strategies and investments would be related to not only for short term cash generation but more so for long term preparation – what we can predict or see, must be prepared for. Finally, across industries, the leaders will embrace a leadership style of humility and accountability towards our societies, our environment, and our consumers.

EA: The pandemic has highlighted how dependent supply chains are on China. Due to this alongside Brexit and the U.S.-China trade war, do you think we are going to see supply chains becoming a bit less global and more “glocal”?

FS: Yes, and that is why I am a Champion of GLOCAL strategy and operating model. We are globally interconnected more than ever before. At the same time, we are more aware and accepting to our local practice, heritage, and national interest. What it does is, it creates stronger clusters of sub-economies and more powerful localized demand cycles, directly linked to local social and consumer profiles. So, business and supply chain leaders must be globally informed and locally equipped to design the roadmap for growth – hence the GLOCAL strategy. Long gone those “one size fits all”, top down mandates from the Head Quarter on how to operate business and generate revenue. Undoubtedly, we all have moral, ethical, and legal duties as good corporate citizens to take care of our people, planet, and product. Beyond that, GLOCAL is the way to ride the wave of sustainable growth and success going forward.

EA: In addition to the pandemic, sustainability remains a long-term challenge of our time. Can you imagine supply chains and production processes really being more sustainable in the future?

FS: Not only I can imagine but it is happening in front of our eyes. From the packaging innovation (recycle cardboard tubes for shampoo/conditioner) for our consumer goods to the sustainability discussion in the fashion industry (water consumption and recyclable material usage) – the discussion, innovation, and action towards upholding our sustainability commitment is very REAL and happening NOW.

What I know and strongly believe is that the effective steps towards sustainable practice start long before supply chain and production processes in our value chain. The first step is innovation in product/packaging design followed by consumer awareness and education. Post Covid-19, the “consumer” piece of the puzzle is firmly placed in our social fabric. Now we need to accelerate our momentum in promoting relevant products and services. Less than half a decade ago, we could not imagine AV and EVs as part of our normal urban life. But now Electric and autonomous vehicles are “desired” by our consumers. Companies like Nike promote and leverage their sneakers made with ocean plastics as an “advantage” over competitors to gain consumer confidence.

Companies like Nestle, Unilever and others are heavily investing into automation to improve variability and waste in our manufacturing process. Across all industries there are active and successful projects around localized sourcing and close to market manufacturing operation – big multinational companies are investing more into developing regional suppliers and local partners, rather than maintaining a centralized souring model. These all contribute to our reduced carbon footprint and slower climate change. Maersk, COSCO, CMA-CGA – they have all taken cargo cube efficiency as one of their top KPIs. Even the air cargo companies are retiring old energy inefficient carriers to upgrade their fleet to more cost-efficient assets.

There are endless examples all around us in almost all industries. There is no other way but the sustainable way – companies who do not recalibrate their supply chain and manufacturing to cater this massive shift in consumer preference will be corporate dinosaurs in very near future.

EA: Finally, you are a successful supply chain professional so what would you recommend to graduates who would like to make a career in supply chain management?

FS: My recommendation to the graduates who want to pursue a career in SCM is that it is an exciting time to join the Supply Chain community. The fraternity of supply chain professionals are active and supportive to overall industry growth. So be involved, be engaged, expand your professional network, and maximize the energy in the Supply Chain community.

The need for “sound soft skills” is important from the early stages of career. So just having the “sound knowledge” of tools, processes, digital solutions will help you through the door into an organization. To thrive and continue to grow professionally, the new graduates must invest now in identifying their strengths and opportunities related to communication and leadership skills.

The learning never stops and will never stop – so please always keep an “open/adaptive learning mindset”. Part of that learning is being diversity oriented. Working in APAC or studying in the West does not make someone a supply chain expert – diversity of knowledge in relations to other functions, geography, industry, culture, and operating model – can make one valuable talent for an organization. So be a “Jack of all trade, and master of Supply Chain”. Good luck and have fun.

EA: Thank you so much for taking part in our interview Farzana. You have provided some really useful insights.

If you want to take part in our Supply Chain Ask an Expert series, feel free to contact us at contact@allthingssupplychain.com

Header Image: Avosb – Getty Images

1 comment

What youre saying is completely true. I like your writing style.

Comments are closed.