With the 10th installment of our Transparent Tuesday blog series, I decided to get back to the basics and address the question, ‘what is supply chain transparency?’ When looking solely at the term ‘transparent’, it is an adjective describing something that is easy to perceive or detect. Perhaps more symbolically, for the purpose of supply chain and this blog, transparent describes an article or material which allows light to pass through so that objects behind can be distinctly seen.

An increasing amount of companies are beginning to allow “light to pass through” their supply chain processes. Doors are being opened that were otherwise sealed tight in the past due to the fear of exposing secret supplier and trade information. The fact is, with the amount of information available today, if competitors truly wanted to find your secret supplier, they could. So why not answer the calls from consumers of “where did my (enter product name) come from?” This aspect of transparency, referred to as traceability, is typically what comes to mind when the topic of supply chain transparency is discussed. Companies are shedding light on the journey their products make before landing in the hands of consumers.

Most recently, while watching some reality TV show here in Germany, my attention was drawn to a commercial from Frosta, one of the largest producers of frozen foods in Europe. The company created a separate website for the tracking of the various ingredients used in their production processes. Photos, videos, an interactive map and the opportunity to enter a code from the packaging of a purchased product are all available to interested consumers. For some select products and ingredients, Frosta traces supplier information down to the responsible farmer. I can’t remember what show I was watching, but I sure do remember that commercial. Well done, Frosta!

While traceability dominates headlines and discussions, the topic of supply chain transparency is much broader than providing answers to “where did my product come from?”. Supply chain transparency can be broken down into internal and external transparency.

Internal supply chain transparency

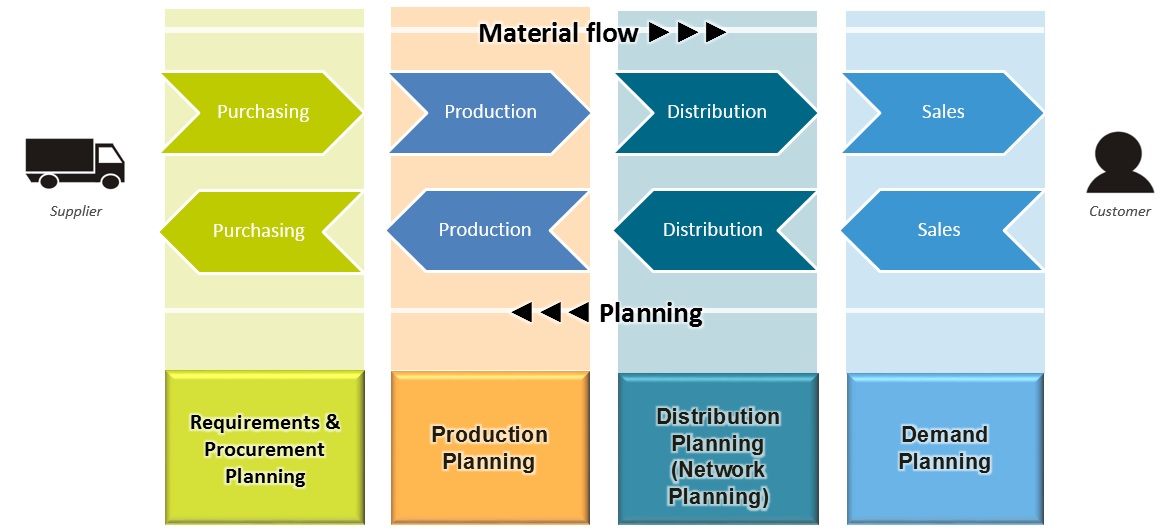

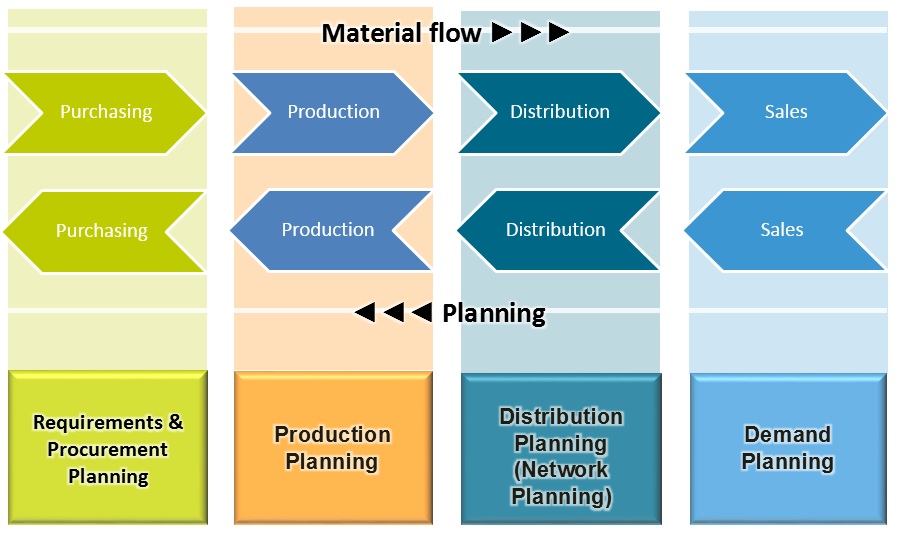

When I say ‘internal supply chain’ I am referring to the purchasing, production, distribution and sales functions:

It is safe to say that, all too often, transparency amongst these four functions is muddy at best. There is a tendency for each department to work in silos, especially if corporate goals are unclear or not aligned. So what does internal supply chain transparency look like?

As seen on the graphic above, materials flow from left to right, while the planning process flows from right to left. Demand planning is at the beginning of the planning process and can serve as a basis for the remaining planning tasks. A transparent and accurate demand plan will include input from all departments and implement intelligent forecast algorithms. Using historical data as well as departmental expertise, demand can be forecasted, and a single plan, accessible to all departments, can be created. With the plan in place, the procurement department knows what to purchase for the production of the goods to be distributed to warehouses closest to the target market.

As everyone involved in supply chain operations knows, even the best laid plans fail. Sales receives an unexpected monster order. A strategic supplier gets hit by a natural disaster making the procurement team scramble. A machine breaks down creating a bottleneck in production. All of these factors increase the importance of establishing strong lines of communication amongst these four functions. It all comes back to the demand plan. If all planning functions are on the same page, alerts can be used to update the plan and automatically create new tasks and warn the respective departments of upcoming supply issues.

In essence, a high level of internal supply chain transparency comes down to the accurate and up-to-date flow of information amongst the four key departments and a single, agile demand plan.

External supply chain transparency

The material flow within the internal supply chain is heavily influenced by external factors, mostly stemming from suppliers and customers:

A major aspect of external supply chain transparency is supplier visibility. The degree to which a company can identify its suppliers varies significantly. Some companies can drill down to sixth and seventh level merchants, while others are lucky to even make it past their first tier dealers. That being said, those companies that are able to dig a bit deeper into their network will find themselves in a better position to deal with risk. A high level of supplier visibility can help companies avoid embarrassing headlines and pinpoint potential threats due to weather or geo-political risks.

A major aspect of external supply chain transparency is supplier visibility. The degree to which a company can identify its suppliers varies significantly. Some companies can drill down to sixth and seventh level merchants, while others are lucky to even make it past their first tier dealers. That being said, those companies that are able to dig a bit deeper into their network will find themselves in a better position to deal with risk. A high level of supplier visibility can help companies avoid embarrassing headlines and pinpoint potential threats due to weather or geo-political risks.

Creating visibility throughout a supplier network is a complex task, but it is slowly shifting from a “nice to have” to a “must have”. Government regulation, for example in the UK, is having an impact on the amount of visibility certain entities are required to have in their supplier network. The Modern Slavery Act serves as one example of these government regulations that are impacting firms on a global scale. A sound supplier relationship strategy can serve as a good basis for the creation of transparency along the external supply chain.

On the other side of the spectrum are the customers. This is where the topic of traceability really takes center stage. Customers want to be able to trust the firms they are buying their products from, and the best way to create this trust is to “shed some light” on operating processes. Consumers not only want to know where a product has its origins, but also seek a high level of corporate social responsibility along the way. This is where a firm’s marketing department comes into play. The press releases boasting new commitments to carbon reduction and sustainable practices, are however only possible with a high level of supplier visibility.

Closing thoughts

Traceability certainly plays a big role in achieving supply chain transparency, but the role of internal processes cannot be forgotten in the quest to become more transparent. It is important to remember the role of sound communication both internally and externally. Silos must be broken down so procurement, production, distribution and sales teams can all work together to achieve shared goals. Open lines of communication with suppliers must be established in order to increase visibility. Honesty and a high degree of openness with consumers will go a long way toward improving a company’s image. The combination of these aspects represents the multi-faceted world of supply chain transparency.

What other aspects of supply chain transparency do you consider important to your operations?

1 comment

[…] tracing tools in the past, but examples include sourcemap, and even in-house applications such as Frosta’s solution I presented in my previous Transparent Tuesday […]

Comments are closed.