Vilfredo Pareto was a renowned Italian engineer, economist and sociologist. Given his success in these diverse fields, it is not surprising that his passion for gardening is often overlooked. However, to some extent, today’s economical world has been shaped by an incident which occurred in his garden.

With the scent of basil and oregano heavy in the air around him, Signore Pareto probably sat on a wooden bench as he observed one particular area of his garden with curiosity. He realized that 20% of the peapods he had sown, produced 80% of the peas. He then wondered if there was a principle to it. Following further research, he also found that 20% of the Italian population held 80% of his country’s wealth.

I have to admit that I don’t really know which event came first (or if Pareto was a fan of basil). But I like the thought that the so called Pareto principle, named after the scholar himself, originated from an everyday observation in an Italian garden. While the discovery of the 20-80 rule was made in a similar way as the Apple-Newton-Incident, at least Signore Pareto did not suffer a headache after his revelation.

You have probably already heard of the Pareto principle, which states that roughly 80% of effects come from 20% of the causes. This principle can be witnessed in most warehouses, where 20% of the items make up 80% of the total stock value. As a result, when the time comes for the annual inventory count, this phenomenon can be put to good use.

Your business will most likely carry out either a full inventory count or periodically conduct cycle counts as a more advanced procedure for counting stock. In any event, 100% of the items are being counted fully at least once per year. In both cases, your business will have to invest a lot of time, effort and money in order to complete this laborious task. I have already discussed the perils of involving too many people in the inventory counting process and in my last post. I presented inventory sampling as the optimal solution to this problem.

The estimation procedures (one of two mathematical approaches) used in inventory sampling relies heavily on the Pareto principle. Given that a relatively small number of items make up most of the total stock value, it is vital to focus on those items more closely than the rest. Here, even a small counting error will have a big impact on the results, whereas if a small mistake is made concerning a large number of low-priced items, the error will probably not hold any major consequence at all.

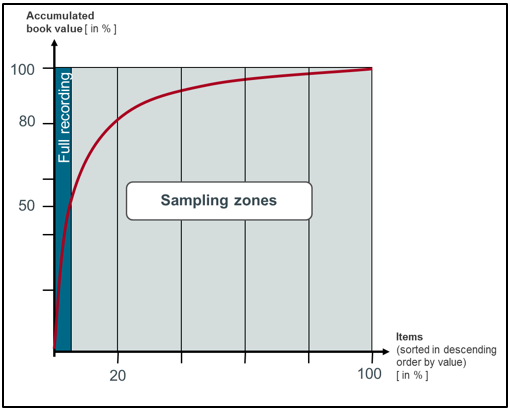

When using inventory sampling, you simply define a full recording area with high-priced items, of which you then count each individual item. In practice this area comprises 50% of the total value rather than 80%. However, the more “Pareto” your warehouse is, the smaller the full recording area becomes.

All remaining items make up the sample area and in order to prevent variances, the sample area is divided into different value zones, from which further samples are taken.

The inventory results from those zones are then extrapolated to the total zone value. Through combining the full recording area and sampling zones , you receive complete inventory results, which not only require less effort to achieve compared to other procedures (counting just about 5 to 15% of all items), but are also more accurate.

No doubt many of you are questioning how this is possible. A manual count is typically prone to error and given that a lot of people are involved, these errors are multiplied. The statistical error produced by the mathematical approach is much lower – and the results get even better the bigger the warehouse is. This is based on 35 years of experience of inventory sampling in Germany, where it is one of the most commonly used methods of stocktaking.

We received a lot of feedback on my previous post and some people wondered, if their inventory accuracy would be affected if they “just relied on” sampling. Let me quell your fears: It won’t. That’s because inventory accuracy is not the goal, it is a prerequisite.

For estimation procedures (described above), the prerequisite is a maximum of 2% inventory difference from the previous full physical inventory count. So if you’re worried about inventory accuracy, you should probably start with inventory management. While it is possible to use inventory counting as a controlling tool for inventory accuracy, the most common purpose of stocktaking is for providing auditors with accurate inventory information.

So what can we learn from the wise Signore Pareto? If your inventory accuracy is good and the distribution of items in your warehouse meets the Pareto principle, you should try inventory sampling and save your company some money.

While the Pareto principle highlights the discovery of an economical phenomenon, the story also explores the curious nature of an active mind. Next time you visit your garden, check your surroundings. Maybe you will discover a principle that will have a beneficial impact on your warehouse processes.

3 comments

Great post.

Due to the large response and numerous discussion points we have had (on LinkedIN) regarding the inventory sampling procedure we have decided to offer a webinar on the topic. You can read more details here: http://www.inform-software.com/products/invent-xpert/events/webinar-invent-xpert/invitation/

Thanks for some thoughts! I certainly believe that having warehouse management systems is important. Every business should employ its use to avoid any problems.

Comments are closed.