Knowing what is on hand in a particular warehouse at a given point in time is of utmost importance. That is why stocktaking procedures should not be taken lightly. As mentioned previously on this blog, statistical inventory sampling provides for an effective alternative to full physical counts and can also serve as an excellent controlling tool. (For those of you who are interested in reading up on our previous articles on the topic, simply click here)

Over the last several months, I have had the opportunity to hold numerous conversations with warehouse managers across Europe and in North America. During this time, I have noticed some common misconceptions regarding the statistical sampling approach, so I would like to attempt to provide some clarity on three major points.

1. Statistical inventory sampling is just a gimmick/shortcut

Right off the bat I would like to throw the word “gimmick” off the table. It is not a trick! Statistical inventory sampling has a storied history dating back to at least the 1950’s and the counting process is based on mathematically sound statistical algorithms.

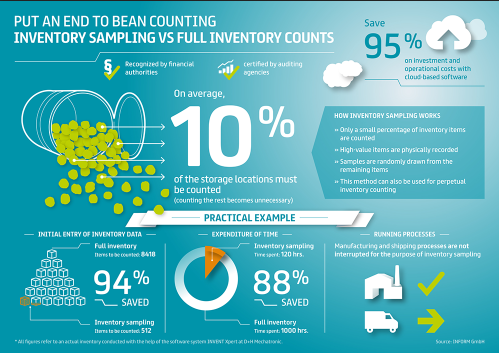

Furthermore, in my conversations the term shortcut came up, more often than not, carrying a negative tone. As far as the term “shortcut” is concerned I would like to differentiate between negative and positive shortcuts. A negative shortcut would be for example hitching a ride or cutting through checkpoints during a marathon, much like Rosie Ruiz did during the Boston Marathon in 1980. That is cheating, and thus a negative shortcut. Then there are positive shortcuts. I find, for example keyboard shortcuts to be quite positive. This infographic below displays why statistical inventory sampling can also be considered a “positive” shortcut. It is, after all, a shorter alternative route to determining inventory quantities (click graphic to enlarge):

2. Statistical Inventory Sampling will negatively impact my inventory accuracy

False! Statistical inventory sampling can be used to CONFIRM inventory record accuracy. For example, at the end of an item group “A” cycle in a cycle counting program, statistical sampling can be used to confirm the accuracy of ALL A items, before beginning the new cycle. This is one major difference to cycle counting as statistical sampling can provide an overall status report for “A” items, or a complete warehouse at a given point in time, which can prove quite helpful from an inventory accounting viewpoint.

As far as substituting statistical sampling for full physical counts is concerned, the Public Company Accounting Oversight Board in the USA states, “In recent years, some companies have developed inventory controls or methods of determining inventories, including statistical sampling, which are highly effective in determining inventory quantities and which are sufficiently reliable to make unnecessary an annual physical count of each item of inventory…” The full passage can be read here.

One last argument to the point of accuracy: Simply put, fewer items counted provides for less opportunity for human error during the counting process. Counting 1,000 items vs. 10,000 items leaves a lot less room for human error.

3. Statistical inventory sampling will require me to change my existing counting procedure

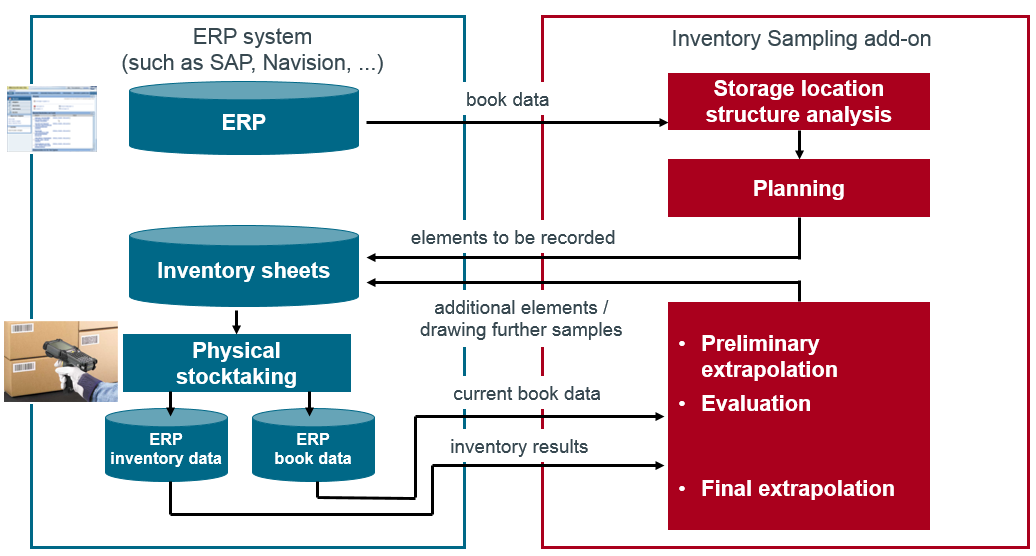

It is common practice for companies to generate counting lists and other counting documents, either for full physical counts or cycle counting procedures, using an ERP system. This does not change when using an add-on statistical inventory sampling system. The add-on bolts right on to an existing ERP system and using a simple data interface, information can be exchanged between the two systems. The major benefit of using the statistical sampling approach is the much shorter version of the counting list that is generated. As seen on the infographic above, the company D + H Mechatronic was able to count 512 items instead of 8,418 items, and they were delivered results for an entire warehouse population with as much accuracy, if not more accuracy, as the results of a full physical count. Here is an example of a statistical sampling counting procedure using an ERP add-on:

Conclusion

Conclusion

I am sure, that despite clearing the air on these three misconceptions, there are still lots of question marks out there. I encourage you to use the comment field below or contact me directly as I am always keen on discussing the topic of statistical inventory sampling as well as other best practice stocktaking procedures. I also provided an example of a public utilities company utilizing this statistical sampling approach. In addition to supplying water, the publicly owned company also provides local residents with electricity, natural gas and long distance heating. I would be happy to send you a copy of the story.