For the fourth year, All Things Supply Chain was invited to attend the annual Supply Chain & Logistics Summit & Expo. Personally, it was my first time in attendance. It was a privilege for me to be able to join the supply chain community in Barcelona, representing the blog and learning from professionals throughout the industry. Over the course of the three-day event, I attended 19 talks, delving into topics ranging from transparency to integrated business planning.

This year, the summit included topic-based tracks focused on strategic planning and management, logistics excellence and technology development. During the event, tweeting key learnings from the various talks was a main objective of mine. To see my tweets throughout the event, click here.

In my opinion, there were quite a few subjects, which stood out amongst the rest, but if I were to focus on my personal top three takeaways, they would go something like this:

- Digitalization is becoming a standard in the industry. Trained digital supply chain workers are needed to unlock potential supply chain dimensions, therefore changing the known working environment.

- Forecasting and contingency planning is now essential due to the ever-changing and unpredictable external environment, e.g. Brexit.

- Consumers are continuing to ‘lead the way’ by setting higher quality and delivery standards.

Sustainability

One topic that really led talks throughout the event was sustainability, and its rising importance not only in the eyes of supply chain managers, but also consumers. Sustainability has been spoken about more and more over the past couple of years; at the event, it was implied that this would continue to rise and even become essential to the success of operations. There are certain expectations from consumers of how companies should be operating their businesses, and how the integration of environmentally friendly practices throughout a supply chain does have more of an effect on purchasing than ever before. This has sprung from a desire to know exactly how a product is made, and most likely from the rise of transparency in supply chains.

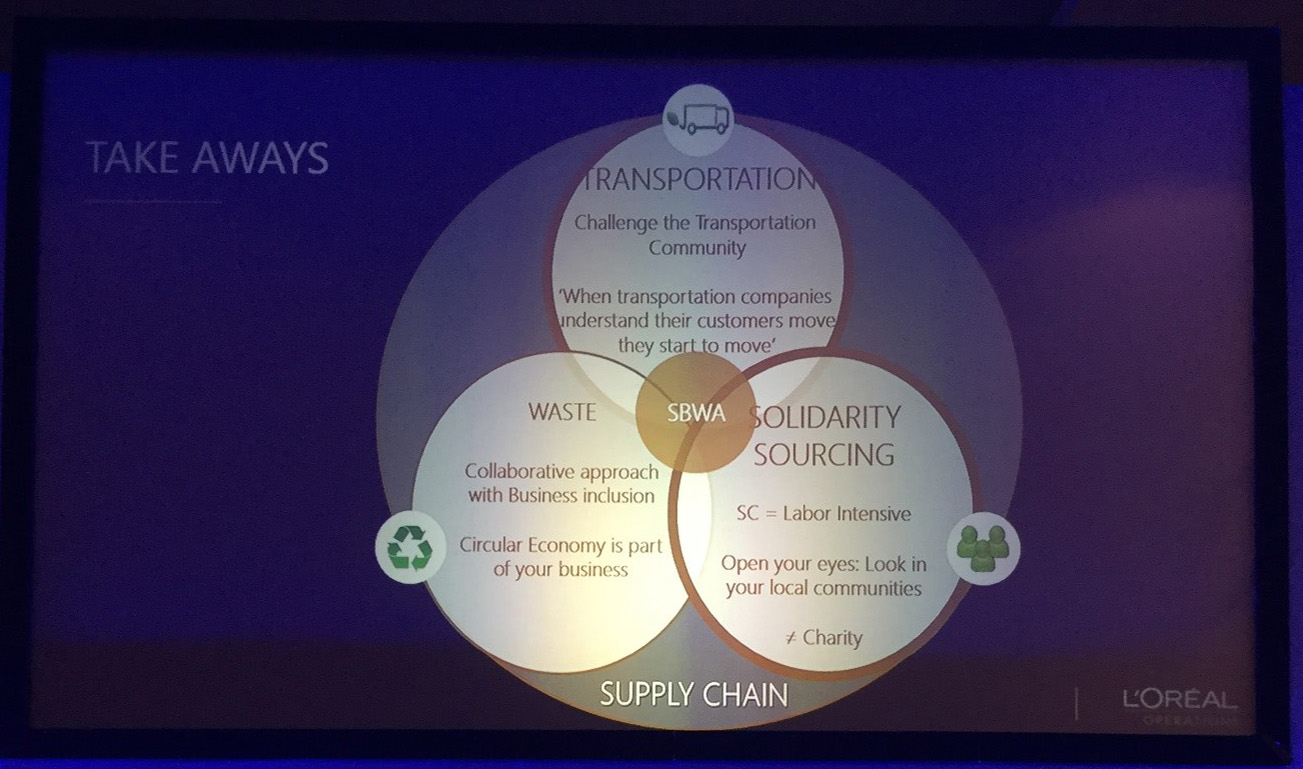

In his talk ‘How to achieve a sustainable supply chain’, L’Oréal’s representative François-Régis expressed how sustainability has to be embedded into operations, specifically “Sustainability is not an option, it’s a license to operate.” This particular quote was used as an example in another talk later on in the event, showing how sustainability is not just a trend, but in fact imperative to future supply chain operations. François-Régis reiterated how setting goals for sustainability will most likely disrupt and completely change supply chains due to their ambitious nature, but are imperative for dealing with the rising environmental threats entering supply chains and adhering to consumer expectations.

Here you can see a picture depicting L’Oréal’s ‘Sharing Beauty with All,’ a program that is focused on creating a sustainable supply chain in all operations, including transportation and wastage:

Co-opetition

This year, there was also a focus on collaboration. David, who attended the previous event, also wrote about this topic in last year’s event review. However, the way collaboration is being used in the industry is now evolving. While attending the talk ‘Supply Chain Collaboration at Scale’ delivered by representatives from 2degrees, Cranfield University and the Co-Operative Group, the focus was on suppliers across industries working together to help aid operations. The cooperation competition concept, also known as ‘Co-opetition,’ was explored; suppliers that are involved in a hostile relationship, which also consists of friendliness due to common interests. Collaboration of suppliers from different industries can help strengthen and create value for companies, engaging in neutral topic-based conversations to aid in continuous improvement and innovation through the increased scale and diversity of interactions.

The newly introduced platform ‘Manufacture 2030’ was the example used in this talk. It is a sustainable manufacturing platform connecting companies and their manufacturing suppliers together to build a new level of trust, helping cut costs, risks and environmental impacts through cross-industry collaboration. Below you can view an explanative video of the platform:

Digitalization

Of course, digitalization and its accompanying buzzwords such as big data and augmented reality were widely talked about at the event, with a whole stream being dedicated to technology development. Speakers on this track focused on how the rise in digitalization is affecting supply chains and the benefits it can bring.

In the presentation ‘Digital Supply Chain Transformations,’ Cristophe Glatzel from Mckinsey explained how combining digital elements can create a positive business case and increase the future of the business. Companies should be clearly defining a digital strategy, road mapping this from 5 up to 15 years in order to see how their businesses will evolve and what that means for the organizational structure and KPIs. This also helps to pinpoint the company’s current maturity in the industry with regards to adopting new technologies, helping to see where they lie in comparison to competitors or other industries which may have been quicker to adopt. At this moment in time, having aspects of a digital supply chain gives a competitive advantage.

A focus on talent was given throughout the presentation, as well as in other talks, due to the new management skills and capabilities needed to interact with the new technologies. New roles need to be created to transform the traditional business models and mold strategies for the future supply chain 4.0. These digital solutions and business processes need to be fully integrated to achieve new horizons of operational excellence. This new talent was described as the biggest opportunity for cementing a digital supply chain.

Return supply chain

This topic stood out, particularly when Professor Richard Wilding from Cranfield University described the return supply chain as ‘mission critical,’ and that it could now be considered the biggest sector of the supply chain. He stated that there is now a 55% return rate in the apparel industry, therefore its biggest supplier is in fact its return supply chain. He went on to add that the return supply chain is not being treated appropriately with the assumption warehouses already have the means to deal with these returns, which is clearly not the case. There should be more of a focus on the return supply chain due to consumers ever-increasing expectations of products and the challenge of online retailing due to no prior physical contact to the product before purchasing. This means it is more of a challenge to accurately describe a product for a customer’s complete understanding of its size and functions to avoid returns.

Talks to stalk

In many of the talks, companies presented ways in which they have improved certain aspects of their supply chains with innovative ideas. Below are just a few of the standout concepts:

Ikea created a truly end-to-end supply chain initiative, replacing its wooden pallets with recyclable paper pallets. This optimized its transport system due to higher filling rates in shipments.

HP’s 3D-printing solution has simplified its production abilities, giving the example of reducing a 95 part Iron made of 17 different materials to 1 material and 1 part with the use of the machine. Ultimately, the company will reduce its ongoing production costs by 73%.

John Lewis introduced ‘Black 5day’ to be able to cope with demand around the Black Friday shopping event every November. This helped to spread out deliveries, therefore eliminating pressure on its logistics capabilities from just one day’s trading.

Closing thoughts

I would like to take this opportunity to thank the new organizers of the event, Clarion, for successfully bringing together all the attending supply chain professionals and putting on an informative and interesting summit. In my opinion, the event definitely served as a good platform for professionals and experts to present the current and up-coming trends in the supply chain industry. The numerous networking opportunities cemented the success of the event and allowed attendees to take full advantage of the Poken connecting devices, which were given as an alternative way to exchanging business cards.

Thank you to all the attendees and speakers; I had a wonderful event and look forward to expanding my knowledge in the future through similar platforms.

What trends have you noticed arising so far in 2017? If you were also at the event, what were your top takeaways?

1 comment

[…] research I have done for the blogs and wrap-ups, as well as the insightful knowledge I gained from attending the Supply Chain & Logistics event in Barcelona. I have been lucky enough to have networked with industry experts and spend my time reading many […]

Comments are closed.