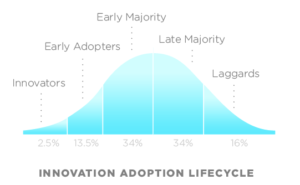

All trends follow a similar trajectory, known as the “adoption lifecycle” where a very small group of innovators and early adopters lead the way, solving the key challenges and paving a path for the rest of the world to follow. One example of this is the now ubiquitous technology of ecommerce. A few pioneers like Amazon and Ebay invented it, developing the key tools to make it possible. Then, over time, the rest of the world followed; now it’s a part of our daily lives.

The transition to sustainability within supply chains is no different. In our transition to a more sustainable economy, techniques for building environmentally friendly supplier relations are still in the early adopter phase.

Here are 5 ways brands leading this transition are developing partnerships with environmentally friendly suppliers as a means to making their supply chains more sustainable.

Developing and funding a team

Leading brands have the foresight to see where the economy is headed and they are investing considerably in making their supply chains more sustainable. Innovators like Patagonia have known for years that “environmentally friendly” isn’t just a good marketing buzzword to help them gain an edge over competitors. A more environmentally friendly supply chain is a more reliable one; They are less likely to succumb to changes based on environmental factors, suffer short or long term shutdown from violations, and are generally ahead of the curve on trends like transitioning to renewable materials – which cost other suppliers time and money to catch up on.

Leading brands also understand that if you don’t allocate resources, you won’t reach your goals. That’s why innovators in this space are building an adequately funded team to make sure they get it right. Developing partnerships with environmentally friendly suppliers is not an assignment for your existing procurement manager ( although it should include them). This is a task for a dedicated team with clear performance targets tied to your brand’s desired outcomes.

Larger brands tend to have their own internal team. Smaller brands often find it more cost-effective to hire an outside firm to help them with this transition. Many brands use a combination of the two. Regardless of the method for execution, most brands are going to follow the next few methods for building successful partnerships with environmentally friendly suppliers.

Clarifying incentives for “going green”

Brands who are ahead of the curve in this space start with the end in mind. They define and keep clear an understanding of how partnerships with environmentally friendly suppliers fits into their vision of the future for their company and its employees. This clarity in vision is the glue that keeps teams together and the fuel that motivates them to get things done.

The whole team should know what the targets are and it should be clear to everyone when they reach them. A practical method for clarifying incentives is to write down the end goal, several specific milestones to hit along the way, and a detailed plan of action beneath that. In preparation for transitional journeys like this, successful teams also brainstorm potential roadblocks along the way and visualize how they will overcome those challenges, should they arrive.

Defining criteria for suppliers

After a brand has a clear vision of where they want to go with their sustainability plan and what “environmentally friendly” means to them, they can develop specific criteria from which they will evaluate potential suppliers. Defining this criteria is important because it provides a scoring rubric the brand can use to evaluate the quality of their suppliers and can make consistent decisions about how to proceed in various situations.

For example, your brand may have a scoring rubric for evaluating suppliers that results in a final score of xx/100. You may only accept to work with suppliers that can attain a 90/100 or higher. You may also have some “deal breaker” points that automatically disqualify a potential supplier, such as the improper disposal of waste materials.

Brands do not have to reinvent the wheel to create a framework for their environmental standards. There are multiple frameworks already in place such as the ISO 14000 family of environmental standards which brands can use outright or build on top of.

Evaluating suppliers

Leading brands have a clear framework and are willing to invest in proper evaluation of new suppliers to make sure they get it right. They understand the cost in timing and lost inventory of having to move to multiple suppliers. If they invest in vetting their suppliers properly from the outset they can reduce problems downstream. Investing in sustainable relationships is more cost-effective in the long run, even if they are paying a little bit more up front to establish these relationships.

They also understand the evaluation itself needs to be properly executed in order for them to get an accurate assessment of their suppliers. Brands utilize experts and industry tools like independent third-party auditors to help them with the evaluations of their suppliers. These third-party auditors are familiar with international standards and are able to adjust their auditing based on your customizations to meet the needs of your brand. Leading brands use third-party auditors for initial evaluations, continual compliance monitoring, and corrective action planning.

Finding new suppliers or correcting existing suppliers

When a brand has determined that one or more of its existing suppliers is not meeting their new sustainability requirements, they generally have two courses of action they can take. The first is to find new suppliers that do meet their requirements. The second option is to implement a corrective action plan and help their supplier become more sustainable.

Generally a brand is going to make this decision based on how extreme the violations of their requirements are. If a supplier only has a few areas that need to be corrected, it’s worth it for the brand to invest in helping them correct it and stay compliant. On the other hand if there are major infractions, they may find it easier and more cost-effective to simply find a new supplier. Brands should have a clear decision matrix or cost analysis framework to help them make these decisions in a methodical manner.

About The Author

David Evans is a freelance writer covering sustainability challenges and solutions. He writes to help companies and consumers understand the environmental and ethical challenges in products and their supply chains so we can find viable solutions for both. See more of David’s writing at: Plastic.Education or follow on Twitter: @plasticedu